Grain to

Glass

FAMILY, QUALITY, CRAFT

Since 1935, Heaven Hill Distillery has focused on the importance of both family and creating quality Whiskeys. We believe that quality Whiskeys come from quality ingredients. And quality ingredients come from long-standing, trusted partnerships that were built on handshakes, not contracts.

Heaven Hill Grain to Glass® highlights this commitment to family and quality by partnering with two family-owned businesses, and taking quality and transparency one step further - starting with the seed.

Crafting Grain to Glass

While many hands were involved in developing Heaven Hill Grain to Glass, it wouldn’t have been possible without a few instrumental people. Hear straight from these key players as they meet up to taste the finished product for the first time.

“QUALITY WHISKEY STARTS WITH THE SEED”

Sonny Beck

The story of Heaven Hill Grain to Glass begins with the seed. Each year, our master distiller works closely with the team at Beck’s Hybrids to identify the ideal non-GMO corn seed varietal that will grow best in Central Kentucky: one that will ultimately yield the best corn for Whiskey-making. Beck’s 6225 was our selection for the second edition of Heaven Hill Grain to Glass.

Family Farms First™

Family farms are the lifeblood of America—making up 97% of all U.S. farms. Without these independent growers tending the soil and growing the seed, family-owned distilleries like ours would not have what we need to bring you quality Whiskey.

That’s why we’re proud to support family-owned farms through our Family Farms First initiative. A portion of every sale of Heaven Hill Grain to Glass—up to $100,000 annually—is donated to Farm Rescue: an organization dedicated to providing farm and ranch families with aid in times of crisis. Together, we can ensure that American farm families don’t just survive, but thrive. Learn more about Farm Rescue’s mission on their website.

Three Families, One Line of Whiskey

Family-owned businesses are built differently—in the way we prioritize people,

quality and our traditions. For Heaven Hill Grain to Glass, we partnered with two

like-minded companies, Beck’s Hybrids and Peterson Farms, which share our

commitment to quality and a passion that’s been passed down for generations.

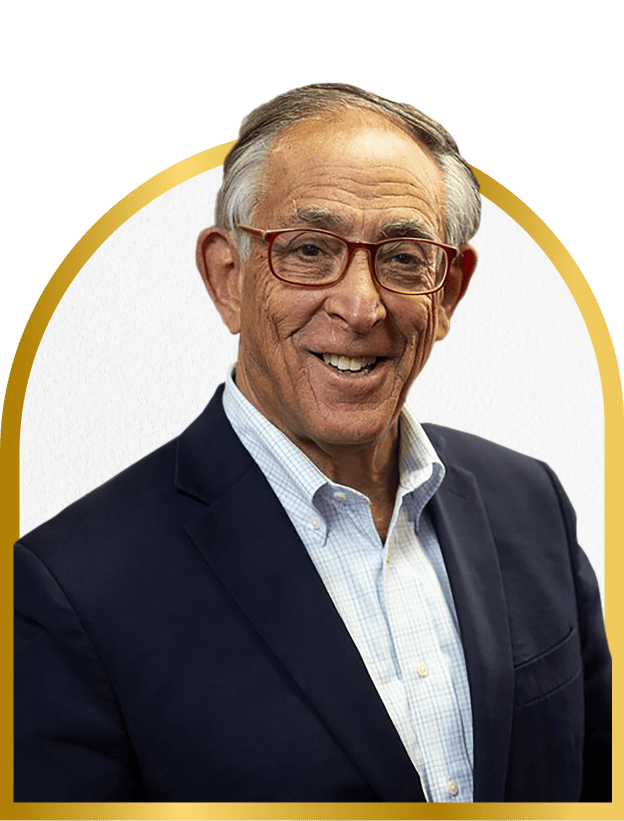

max shapira

HEAVEN HILL DISTILLERY

Heaven Hill Distillery has been owned and operated by the Shapira family since 1935.

In 2017, third generation president, Max Shapira, had the idea to take craft Whiskey

one step further, starting with the seed: one that would grow best in and around

our home in Central Kentucky.

SONNY BECK

BECK’S HYBRIDS

In order to find the right corn seed, we turned to the expertise of Beck’s Hybrids, a family

-owned company established in 1937 and based out of Atlanta, Indiana. We started by

meticulously selecting corn plants that had the attributes we wanted for Heaven Hill Grain

to Glass: higher starch content, better yield and, most importantly, the ability to thrive in

the soil of Central Kentucky. Those plants were then crossed to create a corn seed hybrid

that would give us the highest quality Whiskey.

BERNARD PETERSON

PETERSON FARMS

Peterson Farms in Loretto, Kentucky, has thirteen generations of history as a family-owned

business. They’re well-known in the Whiskey industry for producing high-quality grains and

pioneering sustainable farming practices to keep the soil healthy. We knew they were the

perfect partner to bring our corn seed varietal to life—right in our backyard.

SEED, SOIL & SPIRIT

The Seed

Each annual edition of Heaven Hill Grain to Glass features a unique corn seed varietal. These corn seed hybrids are specifically bred to thrive in the soil and climate of Central Kentucky. They also yield corn that will produce exceptional Whiskey. It can take years, or even decades, to create these hybrids. While selected for desirable qualities such as resilience and overall grain quality, they can also result in new flavor profiles in your glass. In 2018, our Master Distiller and the team at Beck’s Hybrids selected Beck’s 6225 for the second edition of Heaven Hill Grain to Glass. That corn seed varietal is proudly shown on the label for an added level of transparency.

The Soil

We know that using locally-grown crops and maintaining healthy soil are crucial to our success. Our corn is grown on two fields in Nelson County, Kentucky, and near our home in Bardstown; in fact, one is located just across the street from our rickhouses. Crop rotation and no-till farming practices are also essential to our commitment—and help guarantee these fields produce high-quality crops each year. Beginning in 2018, the wheat in Heaven Hill Grain to Glass Kentucky Straight Wheated Bourbon Whiskey was also grown by Peterson Farms in Central Kentucky: further demonstrating the quality and transparency of this line of Whiskeys.

The Spirit

After the grain is harvested and distilled, it ages for at least six years in our rickhouses. It is then non-chill filtered, and for the second edition releases, bottled at barrel proof: highlighting the unique characteristics and flavors of the grain. The result is a truly premium product with a limited number of bottles produced each year. For our 2025 releases, the barrel entry proof for Heaven Hill Grain to Glass Whiskeys was 107. Historically, this was Heaven Hill Distillery’s traditional barrel entry proof, and it was important to us that we honor it in this new line of contemporary Whiskeys. Heaven Hill Grain to Glass is the result of many teams working together. From the farmers who plant and harvest the fields, to those who roll the barrels into each rickhouse, countless people are involved in bringing these expressions to life. Their spirit and passion shine through in every last drop.

Tales from the Hill:

Grain to Glass

Podcast Series

The Seed of An Idea

The first episode in this three part series explores the importance of quality ingredients to quality Whiskey, illustrating how Heaven Hill Grain to Glass takes our dedication to excellent Whiskey a step further and reveals a new level of transparency behind the process.

It Starts with the Seed

For each annual release of Heaven Hill Grain to Glass, we hand-select a unique corn seed varietal. In the second episode of the series, we’re focusing on our partnership with Beck’s Hybrids and how we work together to select the best seed to craft these ultra-premium Whiskeys.

Passionate Farmers,

Exceptional Whiskey

Thanks to the hard work of farmers, we’re able to use high-quality grains in our Whiskeys. In our third and final episode in the series, we talk with Peterson Farms about what it takes to grow Whiskey grains and the importance of using locally-grown crops.

“The Kentucky landscape is a key ingredient in making our Whiskey exceptional”

Conor O’Driscoll

CURRENT RELEASES

- Distillation Year

- 2018

- Release

Date - May 2025

- Bottling Proof

- 105

- Barrel Entry Proof

- 107

- Corn Seed

Varietal - Beck’s 6255

- Rickhouse

Site - W5, W6

- Rickhouse

- Cox’s Creek

- Floor

- 3, 4, 5

- Distillation Year

- 2018

- Release

date - Jul 2025

- Bottling Proof

- 105.2

- Barrel Entry Proof

- 107

- Corn Seed

Varietal - Beck’s 6255

- Rickhouse

Site - W5, W6

- Rickhouse

- Cox’s Creek

- Floor

- 3, 4, 5